Welcome to Infinity Testing Solution

Making Your Testing Process Error-Free, Accurate, and Compliant

We deliver high-precision testing machines, expert calibration services, and advanced material testing solution to ensure accurate, error-free results across diverse industries. Trusted by professionals nationwide for quality, performance, and reliability.

Wide Range of Testing Equipment

From Universal Testing Machines to specialized Hardness Testers, we offer high-precision solution for all your material testing needs.

Expert Calibration & AMC Services

Ensure long-term accuracy and performance with our professional Calibration and Annual Maintenance Contracts for testing machines.

Trusted by 1100+ Clients Across India

We are a preferred choice for industries seeking dependable testing solution backed by quality service and technical expertise.

About Infinity Testing Solution

Delivering Accuracy Through Innovation and Expertise

Infinity Testing Solution is a trusted provider of advanced material testing equipment, including Universal Testing Machines, Hardness Testers, Portable Leeb Testers, Micro Vickers, and Vickers Hardness Testers. With a focus on accuracy and performance, we serve a wide range of industries by supplying reliable instruments like test blocks, diamond indenters, and customized Brinell hardness testers.

Beyond product supply, we also offer comprehensive AMC (Annual Maintenance Contracts) and Calibration Services to ensure the long-term reliability and compliance of your testing machines. Backed by technical expertise and a commitment to quality, Infinity Testing Solution helps industries maintain precision in every test.

Our Expert Services

Our commitment is to ensure unmatched accuracy, performance, reliability, and long-term value for your equipment. Whether it’s calibration, maintenance, or customization, we partner with you at every step to create a seamless and efficient testing environment you can trust.

Calibration Services

Precision calibration services for consistent, certified machine performance every time.

Annual Maintenance Contracts

Scheduled maintenance ensures smooth operation and reduces breakdowns effectively.

Customization & Retrofitting

Tailored solution to match your specific testing equipment requirements perfectly.

On-Site Technical Support

Quick engineer support at your location for fast, reliable, and expert issue resolution.

Our Products

Analogue Rockwell Hardness tester

Analogue Rockwell Hardness Testers for precise material hardness measurement with multiple loads and scale options.

Rockwell Hardness Tester – ITS 150

| Parameter | Specification |

|---|---|

| Load | 60 kgf (HRA), 100 kgf (HRB), 150 kgf (HRC) |

| Max. Test Height | 230 mm |

| Depth of Throat | 133 mm |

| Size of Base (Approx.) | 170 x 430 mm |

| Machine Height (Approx.) | 655 mm |

| Net Weight (Approx.) | 65 kg |

| Other Features | Supports Rockwell D, F, G, E, H, K, L, M, P, R, S, V scales using various indentors and loads |

Superficial Rockwell Hardness Tester – ITS 45

| Parameter | Specification |

|---|---|

| Load | 15, 30, 45, 60 (HRA), 100 (HRB), 150 kgf (HRC) |

| Max. Test Height | 230 mm |

| Depth of Throat | 133 mm |

| Size of Base (Approx.) | 170 x 430 mm |

| Machine Height (Approx.) | 655 mm |

| Net Weight (Approx.) | 65 kg |

| Optional Accessories | Special indenters, master test blocks, 200 mm flat table, 70 mm Vee table |

Rockwell cum Brinell Hardness Tester – ITS 250

| Parameter | Specification |

|---|---|

| Load | 60 (HRA), 100 (HRB), 150 (HRC), 187.5, 250 kgf |

| Max. Test Height | 330 mm |

| Depth of Throat | 150 mm |

| Size of Base (Approx.) | 210 x 474 mm |

| Machine Height (Approx.) | 850 mm |

| Net Weight (Approx.) | 100 kg |

Digital Rockwell Hardness Testers

Digital Rockwell Hardness Testers designed for accurate, manual hardness measurement across multiple industrial applications.

Rockwell Hardness Tester – ITS 150-D

| Parameter | Specification |

|---|---|

| Load | 60 kgf (HRA) 100 kgf (HRB) 150 kgf (HRC) |

| Max. Test Height | 230 mm |

| Depth of Throat | 133 mm |

| Size of Base (approx.) | 170×430 mm |

| Machine Height (approx.) | 655 mm |

| Resolution | 0.1 Rockwell |

| Net Weight (approx.) | 65 kg |

| Loading Unloading | Manual |

| Optional | Special indenters, Different ranges master test blocks, 200 mm Flat table, 70 mm Vee table |

Superficial Rockwell Hardness Tester – ITS 45-D

| Parameter | Specification |

|---|---|

| Load | 15 kgf 30 kgf 45 kgf 60 kgf (HRA) 100 kgf (HRB) 150 kgf (HRC) |

| Max. Test Height | 230 mm |

| Depth of Throat | 133 mm |

| Size of Base (approx.) | 170×430 mm |

| Machine Height (approx.) | 655 mm |

| Net Weight (approx.) | 65 kg |

| Resolution | 0.1 Rockwell |

| Loading Unloading | Manual |

| Optional | Special indenters, Different ranges master test blocks, 200 mm Flat table, 70 mm Vee table |

Rockwell cum Brinell Hardness Tester – ITS 250-D

| Parameter | Specification |

|---|---|

| Load | 60 kgf (HRA) 100 kgf (HRB) 150 kgf (HRC) 187.5 kgf (Measuring with Brinell microscope or BIMS) 250 kgf (Measuring with Brinell microscope or BIMS) |

| Max. Test Height | 330 mm |

| Depth of Throat | 150 mm |

| Size of Base (approx.) | 210×474 mm |

| Machine Height (approx.) | 850 mm |

| Net Weight (approx.) | 100 kg |

| Resolution | 0.1 Rockwell |

| Loading Unloading | Manual |

| Optional | Special indenters, Different ranges master test blocks, 200 mm Flat table, 70 mm Vee table |

Digital Motorized Rockwell Hardness tester

Advanced motorized hardness testers supporting Rockwell and Brinell methods for precise, efficient industrial material testing.

Rockwell Hardness Tester – ITSE-150

| Specification | Details |

|---|---|

| Load | 60 kgf (HRA), 100 kgf (HRB), 150 kgf (HRC) |

| Max. Test Height | 215 mm |

| Depth of Throat | 133 mm |

| Size of Base | 170 x 430 mm (approx.) |

| Machine Height | 655 mm (approx.) |

| Net Weight | 65 kg (approx.) |

| Resolution | 0.1 Rockwell |

| Loading/Unloading | Motorized |

| Optional Accessories | Special indenters, master test blocks, 200 mm flat table, 70 mm Vee table |

Superficial Rockwell Hardness Tester – ITSE-45

| Specification | Details |

|---|---|

| Load | 15, 30, 45, 60 kgf (HRA), 100 kgf (HRB), 150 kgf (HRC) |

| Max. Test Height | 215 mm |

| Depth of Throat | 133 mm |

| Size of Base | 170 x 430 mm (approx.) |

| Machine Height | 655 mm (approx.) |

| Net Weight | 65 kg (approx.) |

| Resolution | 0.1 Rockwell |

| Loading/Unloading | Motorized |

| Optional Accessories | Special indenters, master test blocks, 200 mm flat table, 70 mm Vee table |

Rockwell cum Brinell Hardness Tester – ITSE-250

| Specification | Details |

|---|---|

| Load | 60 kgf (HRA), 100 kgf (HRB), 150 kgf (HRC), 187.5 kgf, 250 kgf (with BIMS) |

| Max. Test Height | 215 mm |

| Depth of Throat | 133 mm |

| Size of Base | 170 x 430 mm (approx.) |

| Machine Height | 655 mm (approx.) |

| Net Weight | 65 kg (approx.) |

| Resolution | 0.1 Rockwell |

| Loading/Unloading | Motorized |

| Optional Accessories | Special indenters, master test blocks, 200 mm flat table, 70 mm Vee table |

Touch Screen Motorized Rockwell

Advanced touch screen motorized Rockwell and Brinell hardness testers with USB, thermal printing, and precise motorized loading.

Touch Screen Motorized Rockwell Hardness Tester – ITS-150-TS

| Specification | Details |

|---|---|

| Model | ITS-150-TS |

| Loads | 60 kgf (HRA), 100 kgf (HRB), 150 kgf (HRC) |

| Max. Test Height | 215 mm |

| Depth of Throat | 133 mm |

| Size of Base (approx.) | 170 x 430 mm |

| Machine Height (approx.) | 655 mm |

| Net Weight (approx.) | 65 kg |

| Resolution | 0.1 Rockwell |

| Loading/Unloading | Motorized |

| Optional Accessories | Special indenters, different ranges, master test blocks, 200 mm flat table, 70 mm Vee table |

Touch Screen Superficial Rockwell Hardness Tester – ITS-45-TS

| Specification | Details |

|---|---|

| Model | ITS-45-TS |

| Loads | 15 kgf, 30 kgf, 45 kgf, 60 kgf (HRA), 100 kgf (HRB), 150 kgf (HRC) |

| Max. Test Height | 215 mm |

| Depth of Throat | 133 mm |

| Size of Base (approx.) | 170 x 430 mm |

| Machine Height (approx.) | 655 mm |

| Net Weight (approx.) | 65 kg |

| Resolution | 0.1 Rockwell |

| Loading/Unloading | Motorized |

| Optional Accessories | Special indenters, different ranges, master test blocks, 200 mm flat table, 70 mm Vee table |

Touch Screen Rockwell cum Brinell Hardness Tester – ITS-250-TS

| Specification | Details |

|---|---|

| Model | ITS-250-TS |

| Loads | 60 kgf (HRA), 100 kgf (HRB), 150 kgf (HRC), 187.5 kgf & 250 kgf (Brinell with microscope or BIMS) |

| Max. Test Height | 215 mm |

| Depth of Throat | 133 mm |

| Size of Base (approx.) | 210 x 474 mm |

| Machine Height (approx.) | 655 mm |

| Net Weight (approx.) | 65 kg |

| Resolution | 0.1 Rockwell |

| Loading/Unloading | Motorized |

Optical Brinell Hardness Testing Machine

Optical Brinell Hardness Testing Machine with auto-focus, customizable stage, precise measurement, and optional computerized reporting.

Optical Brinell Hardness Testing Machine – ITS-3000-O

| 🔧 Feature | 🔍 Specification |

|---|---|

| Model | ITS-3000-O |

| Screen | Optical screen assembly attached to the machine |

| Workstage Size | Customizable; standard 200mm flat table and 70mm vee table included |

| Measuring Range | 1mm – 6mm |

| Focusing | Auto-focused optical tube fixed in machine |

| Workpiece Height | 380mm |

| Measuring System | Optical screen with micrometer; dia-to-hardness chart provided in manual |

| Throat Depth | 200mm |

| Resolution | 1 |

| Movement | Manual screw for sample rest; hydraulic handle for loading/unloading |

| Power Supply | 3 Phase with proper earthing |

| Load | 250 to 3000 kgf in 250 kgf stages |

| Optional Accessories | – Fabricated foundation table – Master test blocks (various ranges) – 5mm & 10mm ball indenters – Double screw machine for heavy samples – Brinell image analysis system for computerized reports |

Computerized Brinell Hardness Testing Machine

High-precision Brinell hardness tester with auto-focus, image software, customizable load up to 3000 kgf, and advanced measurement accuracy.

Computerized Brinell Hardness Testing Machine (Model: ITS-3000-PC)

| Parameter | Specification |

|---|---|

| Screen | Connected to computer via USB camera |

| Workstage Size | Customizable as per requirement. Comes with 200mm flat table & 70mm Vee table |

| Measuring Range | 1mm – 6mm |

| Focusing | Auto-focused camera tube fixed in machine |

| Accuracy | Magnification: ±0.5% |

| Workpiece Height | 380 mm |

| Measuring System | High-accuracy image processing software with auto, semi-auto, and manual measuring modes |

| Throat Depth | 200 mm |

| Resolution | 0.01 |

| Repeatability | ±0.5% |

| Movement | Sample resting screw movement manually. Loading/unloading via hydraulic power pack |

| Power Supply | 3 Phase with good earthing |

| Load Range | 250 kgf to 3000 kgf in 250 kgf stages |

| Optional Accessories | 187.5 kgf loadComputer systemFabricated foundation tableMaster test blocks (various ranges)5mm & 10mm ball indentersCustomizable software featuresDouble screw machine for heavy samples |

Portable Hydraulic Brinell Hardness Tester

Portable Brinell hardness tester with manual hydraulic loading for accurate on-site testing of large metal components.

Portable Hydraulic Brinell Hardness Tester

✅ Working Principle

| Details |

|---|

| Fix the test head of the Brinell hardness tester to the test frame. During testing, the measuring frame is clamped onto the test surface. The hydraulic system uses a control valve to apply a 3000Kgf force. According to ASTM standards, loading should be repeated 3–4 times to maintain 3000Kgf for 0–5 seconds. |

Instrument Features

| Feature | Description |

|---|---|

| Test Principle | Hydraulic loading system up to 3000Kgf using manual operation. |

| On-site Testing | Easy to carry and operate directly on large or fixed components. |

| Permanent Indentation | 10mm ball with 3000Kgf creates a lasting indentation for re-inspection. |

| High Reliability | Fully complies with Brinell testing methods like standard desktop testers. |

| High Accuracy | Indication error and repeatability match ISO & ASTM standards. |

| Wide Application | Can test metal parts of any shape or size when clamped properly. |

| Broad Test Range | Supports different test forces and heads for various metal types. |

Application

| Areas of Use |

|---|

| Testing of steel, non-ferrous metals, castings, forgings, and heat-treated parts. |

| Suitable for oversized parts that desktop testers cannot handle. |

| Offers better accuracy than Leeb testers. |

| Supports automatic measurement of indentations. |

Technical Parameters

| Parameter | Specification |

|---|---|

| Test Force | 3000kg (Optional: 1000kg, 750kg, 500kg) |

| Test Ball | 10mm Carbide alloy (Optional: 5mm) |

| Test Range | 32–650 HBW |

| Dimensions | 350mm Height × 100mm Throat Depth |

| Indicator Error | As per ISO 6506, ASTM E10 |

| Repeatability Error | As per ISO 6506, ASTM E10 |

| Test Force Error | As per ISO 6506, ASTM E10 |

| Weight | Approx. 14 kg |

Standard Assembly

| Items Included |

|---|

| THB-3000 Tester |

| Operating Handle |

| Brinell Hardness Block |

| 20X Reading Microscope |

| 10mm Spare Hard Alloy Ball |

| Anvils (Flat, V-type, Spot-type) |

Optional Accessories

| Optional Items |

|---|

| High/Low Value Brinell Hardness Blocks |

| Hard Alloy Test Balls (5mm, 10mm) |

| Spare Parts: Hydraulic Oil, Capsules, O-rings |

| Maintenance Tools |

| Automatic Brinell Indentation Measurement System (BIMS) |

| Other Chains or Custom Specifications |

Optical Vickers Hardness Testing Machine

Advanced Vickers Hardness Testing Machine with optical screen, precise measurements, customizable workstage, and motorized loading.

Optical Vickers Hardness Testing Machine – ITS-V50

| Feature | Details |

|---|---|

| Model | ITS-V50 |

| Screen | Optical screen assembly attached to the machine |

| Workstage Size | Customizable as per customer requirement; standard: 50mm flat table and 38mm vee table |

| Measuring Range | 0.1 mm – 1 mm |

| Focusing | Focused optical tube aligned with indentation |

| Maximum Test Height | 200 mm |

| Measuring System | Measure diameter using optical screen and micrometer; result via hardness correlation chart (manual method) |

| Throat Depth | 135 mm |

| Resolution | 0.001 |

| Movement | Manual sample resting screw movement; loading/unloading by motor |

| Power Supply | Single Phase with proper earthing |

| Load Range | 5, 10, 20, 30, 50 kgf |

| Optional Accessories | – Fabricated foundation table- Master test blocks (various ranges)- Indenters- Double screw machine for heavy samples- Computerized report system conversion |

Computerized Vickers Hardness Testing Machine

Advanced Vickers hardness testing machine with camera-based auto measurement, customizable software, and precise load options.

Computerized Vickers Hardness Testing Machine – Model: ITS-V50PC

| Feature | Description |

|---|---|

| Model | ITS-V50PC |

| Screen | Connected to computer via machine USB camera |

| Workstage Size | Customizable; standard includes 50mm flat table and 38mm vee table |

| Measuring Range | 0.05mm – 0.4mm |

| Focusing | Auto-focused camera tube fixed in machine for accurate indentation |

| Accuracy | Magnification: ±0.5% |

| Max Test Height | 200 mm |

| Measuring System | Camera image processing software with high accuracy; auto, semi-auto & manual modes |

| Throat Depth | 135 mm |

| Resolution | 0.001 |

| Repeatability | ±0.5% |

| Movement | Sample resting screw moves manually; loading/unloading by motor |

| Power Supply | Single phase with proper earthing |

| Load | 5, 10, 20, 30, 50 kgf |

| Optional Accessories | Computer system, fabricated foundation table, master test blocks, indenters, software customization, double screw machine for heavy samples |

Microscope Inverted Metallurgical Microscope

ITS-1001 is a robust inverted metallurgical microscope with 50X–1000X magnification, LED illumination, and precision focusing system.

Inverted Metallurgical Microscope (ITS-1001)

| Parameter | Specification |

|---|---|

| Model | ITS-1001 |

| Mechanical Body | Single mold sturdy stand with anti-rust materials and extended base for better stability. |

| Trinocular Observation Head | Trinocular head inclined at 45°, interpupillary distance adjustable from 55mm to 75mm. |

| Eyepieces | Wide Field Eyepieces 10X (PAIRED), FOV 18mm, with diopter adjustment. |

| Nosepiece | Reverse angle quintuple nosepiece on ball bearings with positive indexing and soft rubber knurled grip. |

| Objectives (Infinity Corrected) | – Long Working Distance Plan Achromatic M5X- Long Working Distance Plan Achromatic M10X- Long Working Distance Plan Achromatic M20X- Long Working Distance Plan Achromatic M50X- Long Working Distance Plan Achromatic M100X |

| Magnification | 50X to 1000X |

| Mechanical Stage | Size 210 x 180mm, supported on ball bearing guideways with low positioned co-axial stage movement controls. |

| Focusing | Co-axial focusing with ball bearing guideways, large knobs, pre-focusing lever, tension adjustment ring.Coarse motion: 35mmFine: 1.4mm (1DIV=0.02mm) |

| Illumination | KOHLER Epi illuminator with LED/Halogen lamp, adjustable brightness.Field & aperture diaphragm with yellow, green, and blue filters. |

Inverted Metallurgical Microscope - ITS-1003

Precision microscope designed for metallurgical analysis with long working distance objectives, LED illumination, and high clarity.

ITS-1003 Inverted Metallurgical Microscope

| Microscope Model | Inverted Metallurgical Microscope – ITS-1003 |

|---|---|

| Mechanical Body | Single mold sturdy stand with anti-rust materials. Extended base for better stability. |

| Observation Head | Trinocular head inclined at 45°, interpupillary distance from 55mm to 75mm. |

| Eyepieces | Wide Field Eyepieces 10X (Paired), FOV 18mm with diopter adjustment. |

| Nosepiece | Reverse angle quintuple nosepiece on ball bearings with positive indexing and soft rubber knurled grip. |

| Objectives (Infinity Corrected) | – Long Working Distance Plan Achromatic M5X- Long Working Distance Plan Achromatic M10X- Long Working Distance Plan Achromatic M20X- Long Working Distance Plan Achromatic M50X- Long Working Distance Plan Achromatic M100X |

| Magnification | 50X – 1000X |

| Mechanical Stage | Stage size 180mm x 165mm, ball bearing supported with low-positioned co-axial controls for smooth movement. |

| Focusing | Co-axial control with ball bearing guideways, large knobs, pre-focusing lever, and tension adjustment. Fine focus: 1DIV = 0.02mm Coarse travel: 35mm Fine range: 1.4mm |

| Illumination | KOHLER Epi Illuminator with LED lamp, adjustable brightness, field and aperture diaphragm, and yellow, green, blue filters. |

Micro Vickers Hardness Tester

Precision Micro Vickers Hardness Tester with automatic turret, digital eyepiece, LCD touch interface, and advanced functionality.

Micro Vickers Hardness Tester – Model ITS-1000 (ADT)

| Feature | Specification |

|---|---|

| Model | ITS-1000 (ADT) |

| Turret | Automatic Turret |

| Inbuilt Printer | Yes |

| Data Statistic Function | Yes |

| RS 232 Port | Yes |

| Objective Lenses | 10X (Observe); 40X (Measure) |

| Eyepiece | 10X Digital Eyepiece with Built-in Encoder |

| Total Magnification | 100X (Measure); 400X (Measure) |

| Testing Forces | 10g to 1000g (0.098N to 9.8N) |

| Hardness Scale | HV0.01, HV0.025, HV0.05, HV0.1, HV0.2, HV0.3, HV0.5, HV1 |

| Conversion Scales | HRA, HRB, HRC, HRD, HRF, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T, HV, HK, HBW |

| Loading Speed | ≤ 50μm/sec |

| Indenter | Standard Rectangular Pyramid Diamond (136º±0.5º) |

| Minimum Measuring Unit | 0.01μm |

| Hardness Value Range | 8HV – 2900HV |

| Data Display | LCD Touch Screen |

| Loading Method | Automatic (Load, Dwell, Unload) |

| Duration Time | 1 – 99 seconds (Adjustable in 1s steps) |

| Objective & Indenter Alignment | Coincidence Accuracy < 1μm (adjustable) |

| X-Y Testing Table | 100×100mm, Travel Range: 25×25mm, Resolution: 0.01mm |

| Test Space | Max Height: 100mm; Throat Depth: 130mm |

| Light Source | LED Cold Light (24hr continuous, 100,000 hr lifespan, heat-free) |

| Machine Dimensions & Net Weight | 540×260×650mm; 50kg |

| Packing Size & Gross Weight | 710×420×627mm; 68kg |

| Power Supply | 220V ±5%, 50/60Hz (110V available) |

| Standards Complied | GB/T4340, ASTM E384 & E92, EN-ISO 6507, JIS B-7734 |

Universal Testing Machine (Manual Gripping)

Model Series: UTE Series / UTES Series

Universal Testing Machine with manual gripping for accurate tensile, compression, and bending strength measurement.

Universal Testing Machine (Hydraulic Gripping)

Model Series: UTE-HGFL Series / UTES-HGFL Series

Heavy-duty Universal Testing Machine with hydraulic gripping for precise tensile, compression, and bending tests.

Broaching Machine (Motorized V/U Notch)

High-precision, motorized broaching machine designed for V and U notch cutting as per Indian and international testing standards, ensuring accuracy and repeatability.

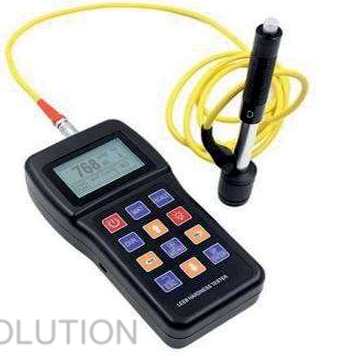

Portable Leeb Hardness Tester

Compact and highly portable digital Leeb hardness tester for quick, accurate, reliable, and non-destructive metal hardness testing.

Double Disk Metallography Specimen Polishing Machine

Double disk polishing machine ideal for metallographic specimen preparation with variable speed, digital display, and precision finish.

Double Disk Metallography Specimen Polishing Machine – ITS-PM

| Technical Specifications | PM-M2 | PM-M2(V) | PM-M2(VD) |

|---|---|---|---|

| Diameter of Polishing Disc | 200 mm | 200 mm | 200 mm |

| Rotating Disc Mode | Fixed | Variable | Variable |

| Rotating Disc Speed | 960 RPM | 50–1250 RPM | 50–1250 RPM |

| Motor Specifications | 180W (A.C) | 180W (D.C) | 180W (D.C) |

| Display Type | — | — | Digital Display |

| Power Source | 220 Volts, 50 Hz | 220 Volts, 50 Hz | 220 Volts, 50 Hz |

| Dimensions (L×W×H) | 720×490×320 mm | 720×490×320 mm | 720×490×320 mm |

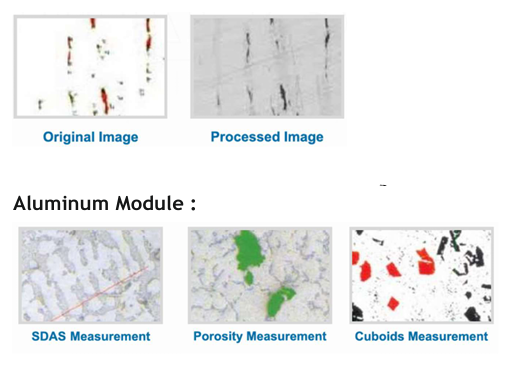

Microstructure Analyser Software

An advanced grain size and phase analysis tool designed to meet Indian and international metallography standards, offering precise image processing

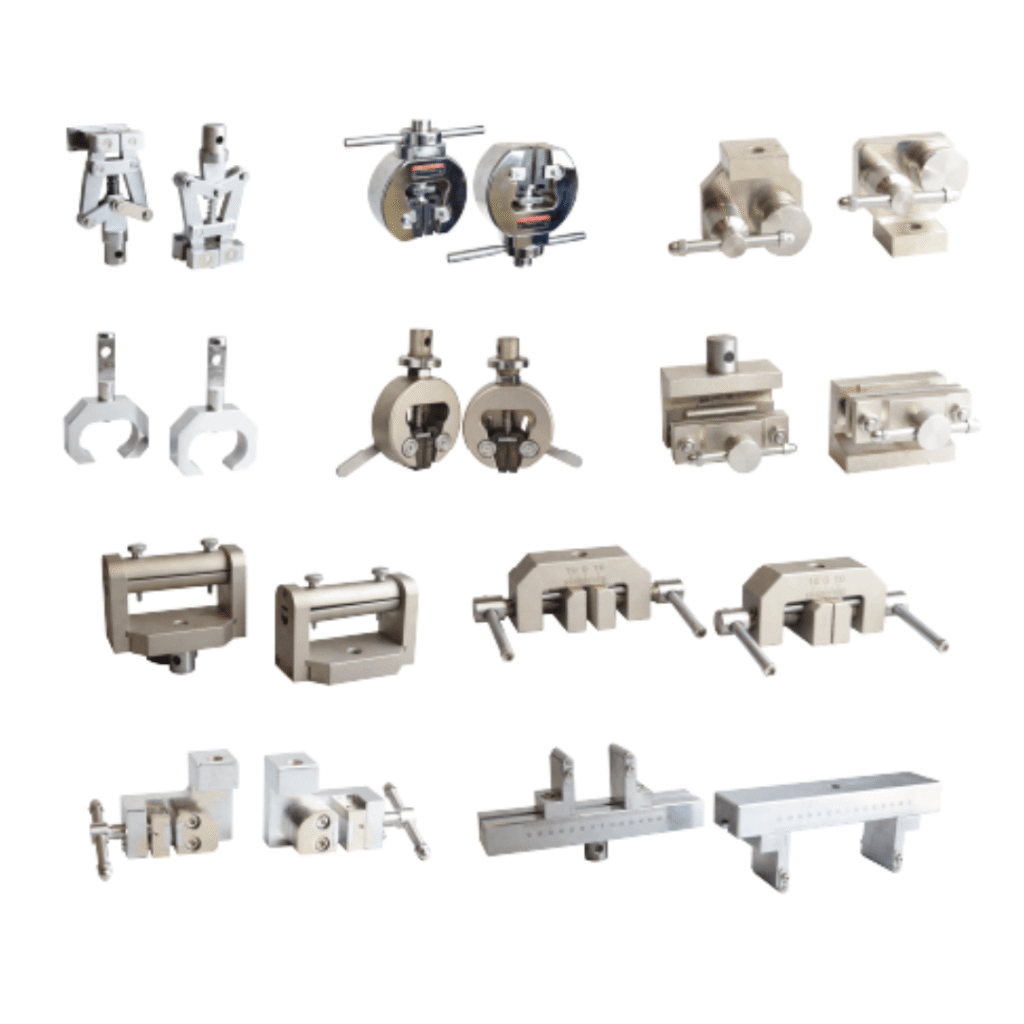

Accessories

We offer a wide range of high-quality accessories and attachments to support material testing and metallurgical analysis equipment.

🧩 Universal Testing Machine Accessories

- Inserts, rack jaws, and pinion shafts

- Special inserts customized as per customer sample requirements

🛠️ Hardness Testing Accessories

- Special indenters for various hardness testing machines

- Master test blocks in different hardness ranges

- Special anvils for accurate sample placement

🔍 Optical Accessories

- Objectives and lenses for Vickers, Micro Vickers, and Microscopes

- Eyepieces and precision optical components

🔩 Testing Attachments & Custom Components

- Bend/Re-bend test attachments

- Shear test and threaded shoulder attachments

- Customized tables and internal machine components tailored to your testing needs

Our Contact Details

Connect With Infinity Testing Solution – Your Partner in Precision Testing

We’re here to assist you with any inquiries about our products, services, or support. Reach out to us using the information below:

Office Address

Infinity Testing Solution

National High School Road, Near Santosa Hotel,

Jawaharnagar, Ichalkaranji – 416115

Maharashtra, India

Phone Numbers

+91 95033 54444 | +91 80109 44946

Email IDs

salesnppindia@gmail.com

connectinfinityss@gmail.com